Papierindustrie

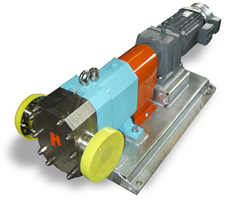

Herold Wendelkolben®-Pumpen

Unsere Verdrängerpumpe bietet einzigartige Vorteile

Gerade bei problematischen Medien bieten wir die richtige Lösung. Herold Pumpen sind genau auf die Bedürfnisse der Papier-Industrie zugeschnitten:

- Produktschonende Förderung von empfindlichen Medien

- Trockenlaufbeständig

- Energiesparendes Förderprinzip

- Gleichmäßiger und nahezu pulsationsfreier Förderstrom

- Sonderwerkstoffe um Verschleiß und Korrosion zu minimieren

Typical Product Applications

- Streichpigmente

- Polymere

- Stärkeslurry

- TiO₂ Fillers

- Kaolin

- gekochte Stärke

- Emulsionen

- Harze

- Retentionsmittel

- TiO₂ Slurry

- Spezialchemikalien

Beliebte Modelle

07.014

Spezielle Materialien reduzieren die chloridische Korrosion.

- Produkt: Kationische Stärke

- Viskosität: 180.000 mPa·s

- Fördermenge: 4,5–15 m³/h

- Druck: 4–7 bar

- Drehzahl Pumpe: 88–227 min⁻¹

- Antrieb: 7,5 kW

02.050

Auch größere Fördermengen sind möglich.

- Produkt: oxidierte Stärke

- Viskosität: 30 mPa·s

- Fördermenge: 45 m³/h

- Druck: 7 bar

- Drehzahl Pumpe: 283 min⁻¹

- Antrieb: 37 kW